Welding is a well-established material process that involves high heat to join two or more parts together. Because of the uneven heat and temperature distribution involved, the final product is always affected by the presence of an intrinsic stress state, even in absence of any external load (residual stress), that may affect its durability.

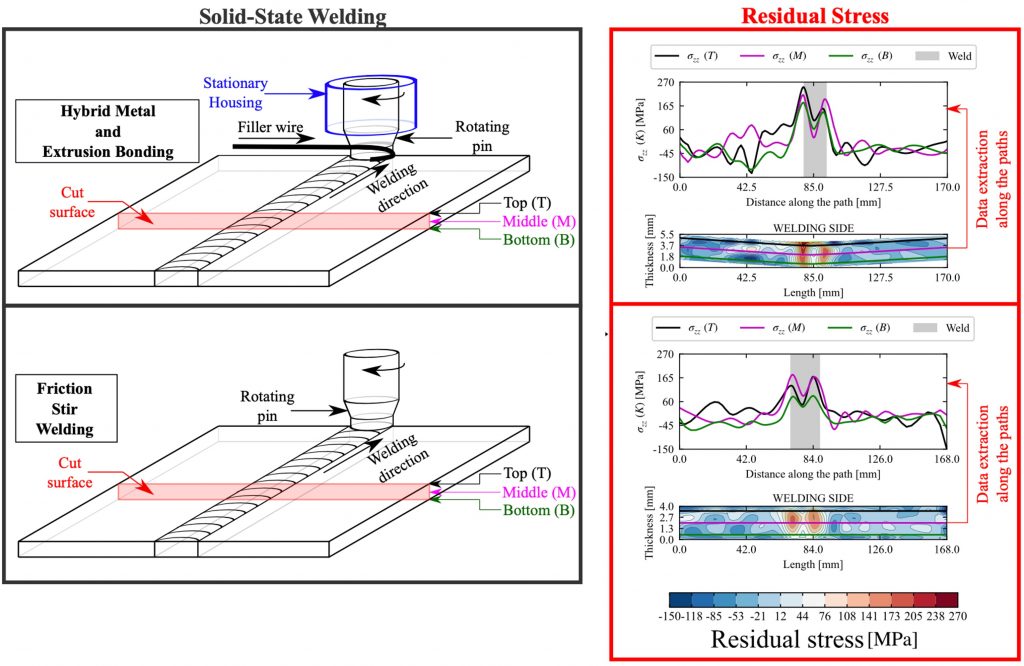

Researchers and manufacturers have striven to mitigate the presence of residual stress in welded structures for years, primarily in fusion-based welding. In this respect, over the last years, remarkable achievements have been focussing on the revisitation and development of new solid-state welding technologies; a broad class of methods allowing materials to be joined below their melting point. More recently, the sophisticated hybrid metal and extrusion bonding (HYB) was developed. HYB is based upon the core technology of the consolidated friction stir welding (FSW) but, it employs an external filler material to consolidate the weld.

Although the presence of residual stress is less severe compared with fusion-based wending, its assessment is of fundamental importance to predict the global structural performance of the joint. Currently, a wealth of literature is available on FSW-induced residual stress, but no one has addressed the investigation of those HYB-induced. This research tries to fill this gap by tackling, for the first time, the evaluation of HYB-induced residual stress and trying to explain how this stress is originated.

A. Tognan, L. Sandnes, G. Totis, M. Sortino, F. Berto, Ø. Grong, E. Salvati. Evaluation and Origin of Residual Stress in Hybrid Metal and Extrusion Bonding and Comparison with Friction Stir Welding. (2022). International Journal of Mechanical Sciences. DOI: 10.1016/j.ijmecsci.2022.107089